2016 Fermentation

- Details

- Published: Monday, 07 November 2016 13:21

- Written by David DeCiero

The 2016 Harvest was a little later than I thought, as September apparently had very little sunshine to help the grapes ripen. The harvest date bounced around a little bit, but it finally happened on October 21st. I was able to pick up the grapes at around 1 pm and get back home by 2 pm. This allowed me to get a breather before starting up the destemmer/crusher. I had a good group of people to help, and the new modifications got a good test. This year, we were able to go through the first 250 lbs of Cabernet Franc in about 1 hour, which was fantastic. The end chute modification ensured a lot less grapes being tossed out the end and on the floor, and the flap on the front chute made sure that no one got hit in the face with any grapes. The simple addition of the piece of plastic and tape on the rod for the gears for the crusher worked almost the entire time. Eventually, it worked itself off, but I had done 500 lbs by that point. Since I ended up with 600 lbs of grapes, this required a person to push the gears back on for the remaining 100 lbs, which is only 3-4 crates. The toughest part is carrying the buckets down into my basement. I tend to make them too heavy, so it is a chore to carry them down. In the future, I may just buy another Brute bucket in order to be able to bring down smaller batches. This would also allow me to lower the height of the stand for the machine and allow for easier access to the input chute.

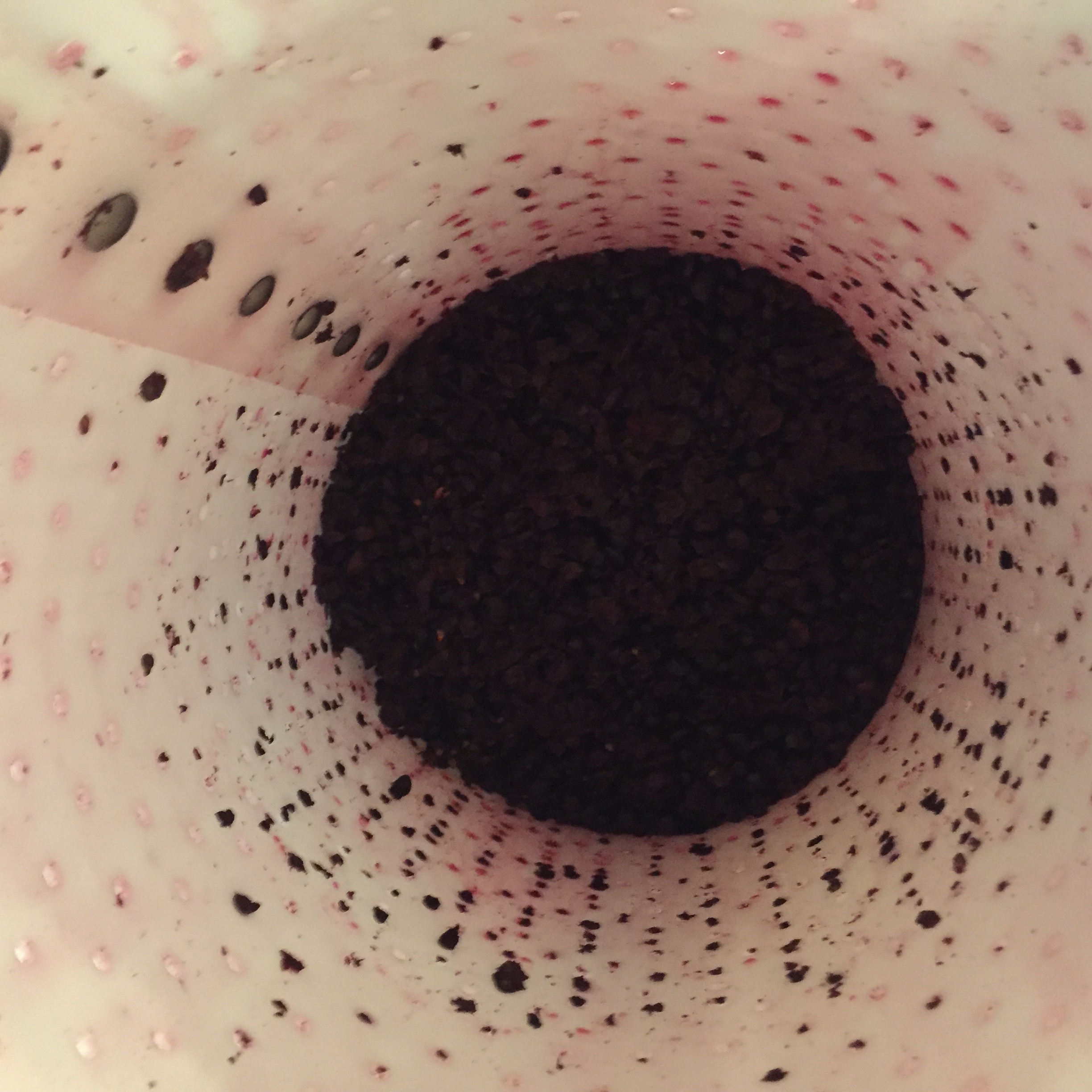

Once the crush was over, the must was a slightly cool 60 degrees. So, I put it in my fermentation chamber to raise the temp up to 65. The next morning, it was 62 degrees and I added my standard additives. The first was Lallzyme EX and OptiRed. These additives break down the cell walls and ensure color stability. After 24 hours, the must had reached 65 degrees and I was ready to rehydrate my yeast and pitch it. First off, I added FT Rouge (a fermentation tannin again for color stability). I then went about rehydrating my yeast. I utilize BM4x4 for the Cabernet Franc and BDX for the Merlot. I had previously used BM45, but the extra lag time causes two pressing days, which is not convenient. It also has some other shortcomings. I rehydrated the yeast with Go Ferm Protect Evolution (1 g per gallon of must in 17 mL of water), waited 15 minutes, added some must (equal to 1/5 the volume of the yeast mixture), waited another 15 minutes and then checked the temps of the must and yeast mixture. Since they were within 15 degrees, I was able to pitch the yeast in the must. The next morning, it was off to the races. I punched it down twice a day (morning and night).

After 6 days (and 1 addition of ½ the amount of Fermaid K at 1/3 sugar depletion), the wine was nearly dry at .998 SG. Overall, it was an extremely easy and hassle free fermentation. The next stop was the press.

The press worked much better this year as the additional holes allowed for the free run to drain more quickly than previously. The sides had the benefit of catching any splashing juice that hit the side of the basket as well. I ended up not actually fastening the sides to the top of the tub, but rather just placing them in the tub. It worked pretty well and I was able to pour the wine in faster since I didn’t have to worry about the splashing. I was able to then press the cake a lot drier due to the extra holes and not having to worry about getting shot with juice. This allowed me to crank up the pressure and get quite a bit of press juice. In all, I ended up with 44 gallons of wine after only 2 hours. One of the things I really like about this press design is that the lees I get are all fine lees. I don’t have to worry about racking again off of the gross lees since there really aren’t any. They go straight into carboys and I am able to inoculate with MLB right away.

After the press was done, it was time to do MLF. Since I had both wines pressed and ready at the same time, this allowed me to only have to buy 1 packet of MLB (which is fairly expensive). I added Optimalo Plus to the wine in the carboys and then rehydrated my MLB (VP41). I use a syringe to measure out the amount of MLB liquid and then squirt that into each carboy. One packet of VP41 will inoculate 66 gallons, so I just scaled the amount up to fit my 44 gallons. After inncoluation, I stir daily for the first week to keep the MLB in suspension and working away. This also helps release some of the remaining CO2 from the end of primary fermentation that builds up in the fine lees. The next step will be sometime in January when I do MLF chromotography to ensure that MLF has completed. In the meantime, I just sit around and wait (and look for those tiny bubbles to see if MLF is occurring).